Aluminum tubes are not unfamiliar in our daily lives. They are commonly found in packaging for cosmetics, glues, hair dyes, paints, etc., and most of the packaging aluminum tubes are beautifully printed. Then why do major manufacturers and businesses add printing to the packaging of aluminum tubes?

First of all, let's first understand the production principle of aluminum tube printing. tube printing refers to the method of printing on aluminum tubes by using the principle of transferring images from an elastic rubber layer. The printing machine used for production generally consists of a printing plate cylinder, an inking device and a blanket cylinder to form a transfer device, which transfers the graphics of each color plate to the blanket, and then transfers the printing graphics to the surface of the tube.

So, what is the powerful role of tube printing?

First, save costs. Compared with traditional manual labeling, printing can print a large number of clear and sharp patterns quickly, and can make full use of the dots to print rich and multi-level color effects, and it is not easy to wear. While maintaining stable quality, it can also save production and maintenance costs.

Second, allow consumers to clearly distinguish between manufacturers and businesses. Each manufacturer and business will design different logos, patterns, texts, etc. according to their own positioning and goals, so that consumers can clearly distinguish the manufacturers and identify a certain brand to achieve the effect of publicity.

Third, to deepen the visual experience of consumers and consolidate the impression of consumers. The exquisitely printed aluminum tube with bright and bright colors is more likely to attract consumers' attention and make them desire to buy. Therefore, the outer packaging of cosmetics and pigments on the market will be designed very exquisitely to meet the visual experience of consumers.

Therefore, tube printing is a link that cannot be ignored in the production process of aluminum tubes. Good graphic design requires excellent product designers to complete; good printing quality should be handed over to a reputable aluminum tube supplier; good aluminum tube can continue to expand market share.

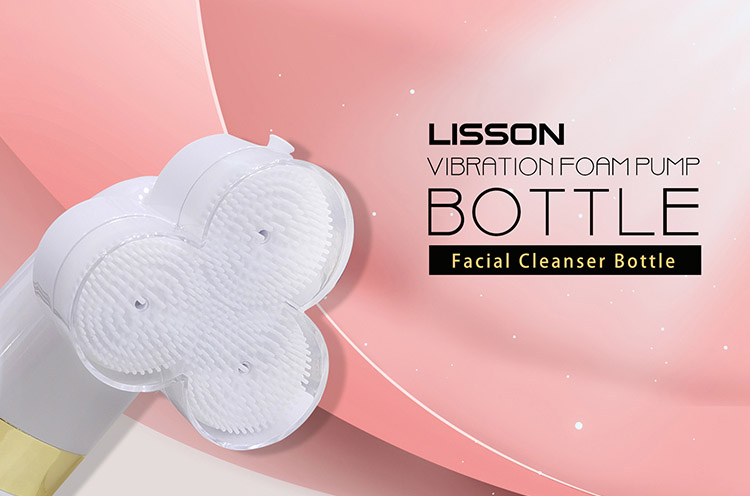

LISSON Packaging has 10 production and printing lines for Collapsible aluminum tubes, with a monthly output of over 3 million pieces. Can print 1~5 colors. Need a packaging solution or quote, contact us now!